BaBylissPro Clipper Blade Types

Blade Technology

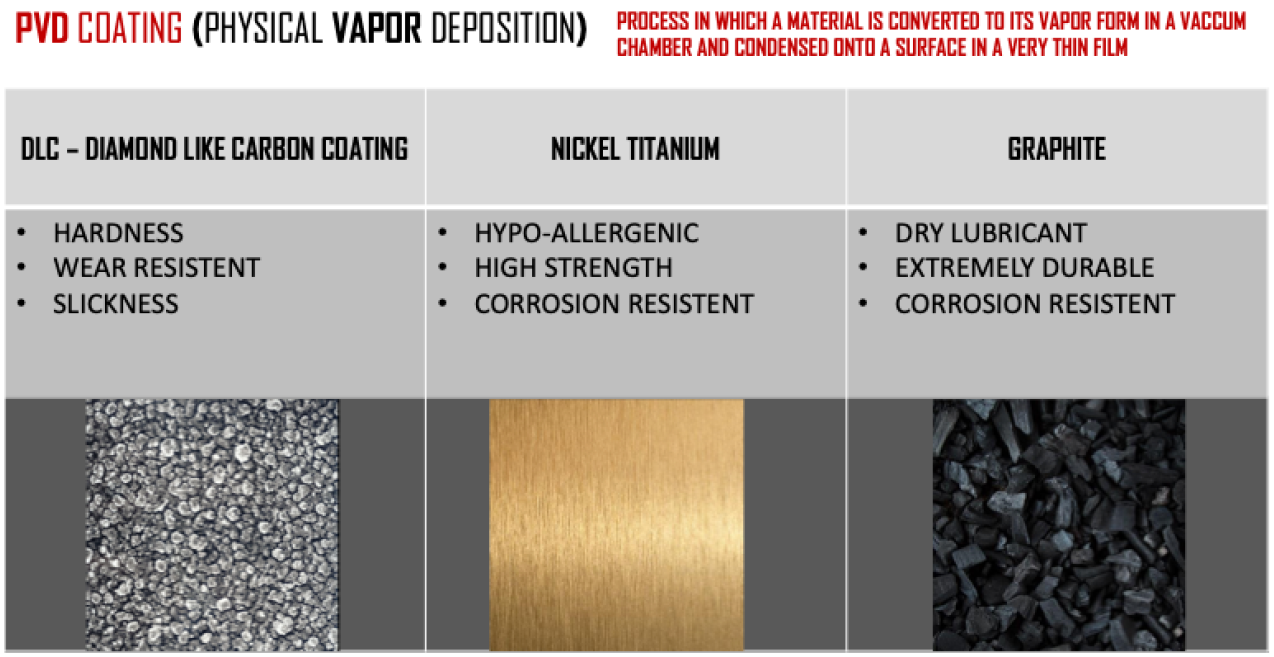

PVD (physical vapor deposition) coating, also known as thin-film coating, is a process in which a solid material is vaporized in a vacuum and deposited onto the surface of a part. These coatings are not simply metal layers though. Instead, compound materials are deposited atom by atom, forming a thin, bonded, metal or metal-ceramic surface layer that greatly improves the appearance, durability, and/or function of a part or product

Clipper Blades

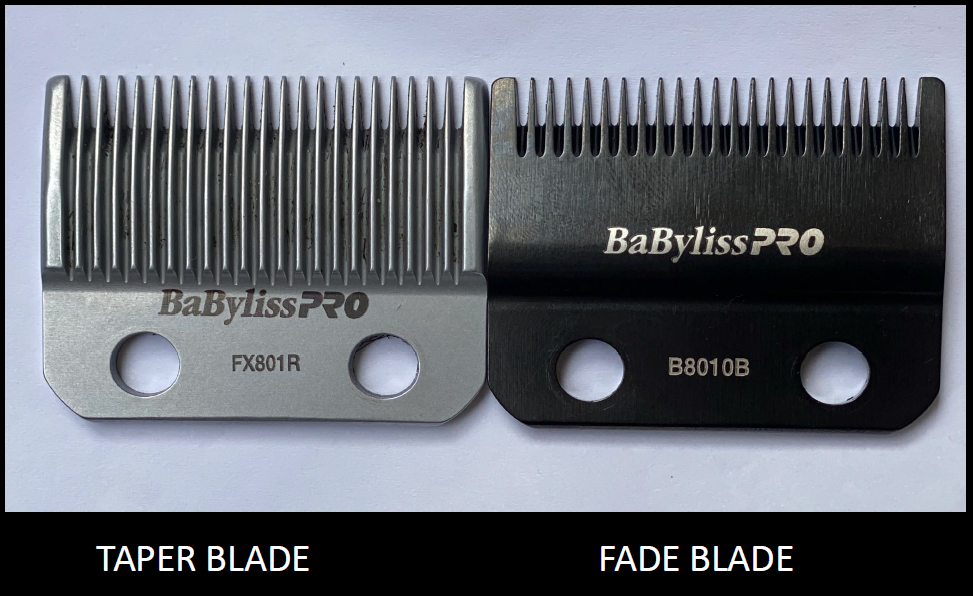

Taper Blade Vs Fade Blade

All Clipper blades are interchangeable. Available as:

109416 – FX802G BarberCo order code 162-701

109417 – FX803B BarberCo order code 162-702

109418 – FX801R BarberCo order code 162-703

109445 – FX8010B BarberCo order code 162-706

109419 – FX8010 BarberCo order code 162-710

Is supplied standard on the Red and White Influencer Clippers and the Gold FX Clipper

* DLC & Titanium coated Taper blade.

* DLC is an acronym for diamond-like carbon. DLC has some of the valuable properties of diamond, including: high hardness, low friction, resistance to wear, no chemical reactions.

* DLC is harder than natural diamond and slicker than "Teflon.“

* DLC coating protects moving parts from abrasion maintaining smooth movement much longer than uncoated parts.

* Nickel Titanium is used to harden and protect cutting and sliding surfaces, corrosion resistant & durable.

* Traditional taper blade.

* Bevelled edge.

* Great for soft fades and blending out.

Is supplied standard on the Black Influencer Clipper

* Black Graphite PVD Coated blade

* Dry lubricant for friction free blade glide, corrosion resistant & durable.

* PVD (physical vapor deposition) coating, also known as thin-film coating, is a process in which a solid material is vaporized in a vacuum and deposited onto the surface of a part. These coatings are not simply metal layers though. Instead, compound materials are deposited atom by atom, forming a thin, bonded, metal or metal-ceramic surface layer that greatly improves the appearance, durability, and/or function of a part or product.

* Fade Blade

* Great for sharp edges

* Effortless fades

* Flatter back of the blades allows for closer fades.

Is supplied standard on the Lithium Rose Gold FX and Silver FX Clippers

* Stainless Steel High Carbon

* High Carbon Stainless Steel is very hard, which makes them good at resisting abrasion and retaining shape. They can withstand significant force.

* Carbon Stainless steel has a higher carbon content, which gives the steel a lower melting point, more malleability and durability, and better heat distribution.

* Traditional taper blade.

* Bevelled edge.

* Great for soft fades and blending out.

Black Graphite PVD Coating Fade Blade

High Carbon Stainless Steel Fade Blade